AESG Builds Quality In to keep Legacy Capital Equipment performing profitably.

Our Founder, Frank Vanella, His Vision And Our Company

My vision for AESG was to create an employee-centric durable goods refurbishment company that draws both from my humble roots and my career in the semiconductor front end that will enable our customers to keep their machine tools performing for decades. I was raised, literally, in an automobile scrap yard run by my parents and staffed by my siblings and me. We were from humble origins and believed passionately in the American dream: that through prayer, hard work, and community, we could both achieve our dreams and serve others. We did not come by these values naturally, nor out of a book, but from my parents. As such, I want to share these dreams. Starting with our employees and the customers we serve.

At AESG, we have an ISO9001-certified rebuild facility, a rarity in the USA. This means we have processes and procedures that enable us to scale with our customers, driving continuous improvement in all we do to delight our customers. The Selective Compliance Assembly Robot Arm (SCARA) Original Equipment Manufacturers (OEMs) we support are mainly out of business and were small unit producers in their day, and as such, maintaining these durable goods is not for the faint of heart. I have learned a lot from textbooks and industry experts about processes, metrology, and inspection tools that form the backbone of semiconductor front-end processing. But it was my parents who taught me to persevere, to soldier on, so that I may serve others.

Fortunately, I was able to begin my career in semiconductor fabrication at one of the most significant plants in the world: IBM in San Jose, CA, back in the 1970s. Yes, we may have had some clean room pterodactyls performing inter-tool automation, but we cranked out high-yield hard drives and other devices. IBM was the definition of vertical integration, and this played into my days in my father’s automobile scrap yard:

- Don’t say you can’t until you’ve tried your hardest.

- Don’t outsource what you can insource.

- Be an Ameri-can, not an Ameri-can’t.

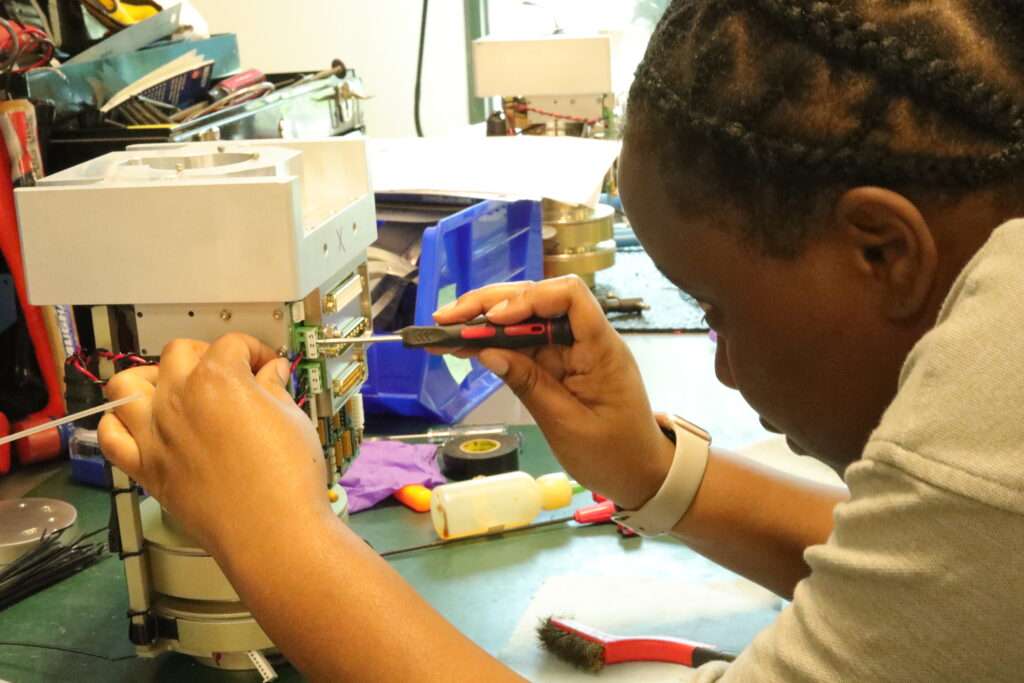

After many years of low particle blood, sweat, and tears at IBM, I moved into semiconductor capital equipment tool automation. First at Equipe, then PRI, then Brooks, and finally at Newport-Kensington. These SCARA suppliers all had a wonderfully American approach to tool automation: very competitive and very customer-focused. I love them all and see the good in each. Yes, they have their challenges. But because I try not to judge, I’ve created a company culture that rewards teamwork regardless of who your parents were, regardless of how much or little you knew of these SCARAs before you started, and regardless of the SCARA OEM. We focus on producing the highest quality rebuilt SCARA because We Build Quality In as we service these automation components. They are not simply binning out good and bad at the end.

We’ve tailored in-process quality checks to the specific robot design, usually, inspection steps the OEMs never performed when they built them originally. We have specific R, theta, and z-axis checks to ensure that regardless of the electro-mechanical design, they perform their absolute best. We track all serial numbers of all the components we’ve ever touched, and each time a component comes in our facility, we check our history with this serial number and make recommendations to our customers based upon our history with this unit.

I’ve saved the best for last: our people. I’m located in Virginia Beach, VA, because of the infinite skilled labor pool our armed services provide for this area. This is counterintuitive for semiconductor capital equipment because most companies want employees with a certain pedigree, education, and work experience. Our team leverages all the same skills our armed services do: high personal standards and an even higher commitment to working as a team to achieve a common goal. Our team looks like America, all different shapes, sizes, and colors because those are the same good souls that sacrifice for the American ideals of a democratic republic: we all participate, we all share in ownership, and we’re accountable to ourselves and those we serve.

If you are looking for efficiency, reliability, and quality built-in, let us know. We are dedicated to providing the highest quality diagnostic and testing techniques for automated equipment repair and refurbishment.