How We Won the West: Semicon West That Is…

aesg1

on

August 25, 2023

How We Won the West: Semicon West That Is...

This year, we had an incredible Semicon West 2023 show, with amazing attendance at the AESG booth. Many folks stayed to break wafers and learn more about the services we deliver and how they can help them keep their legacy capital equipment up and available. In addition, we attended several technical and business-focused events and learned more about the state of our industry—specifically the velocity and trends. Thankfully no one had any 450mm displays. With that disaster behind us, 200mm is better than ever, as there were new tool automation solutions available for 200mm and wonderfully new toolsets that enable die stacking from different substrates and wafer sizes. Thanks to our kind Austrian friends at EVG! All these trends point to a competitive industry that will produce the best results for our stakeholders.

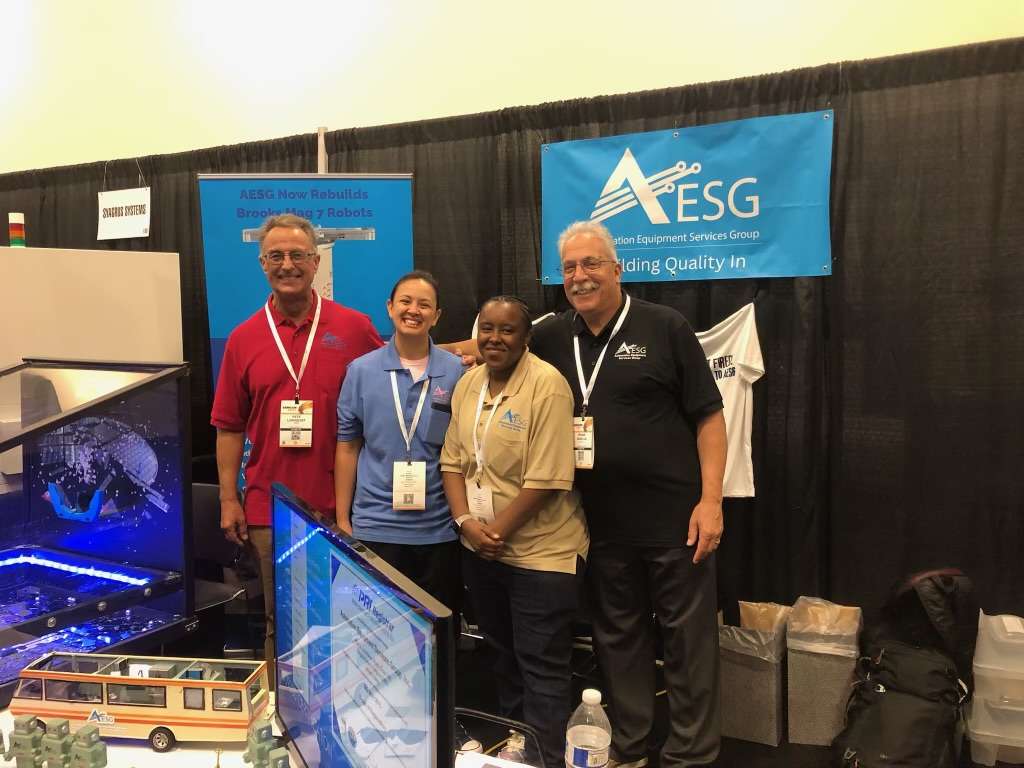

Our business is built upon our engineering technicians’ talents. Yes, our ISO9001 registration means we have world-class processes and procedures in place, but our people drive our success because they work together on any robot/controller that comes to our doors. This past spring, two talented folks attended the Women in Semiconductors session sponsored by semi.org. And yes, Mary Domingo and Trenice White attended West this year. Did they follow up on the discussions from Women in Semiconductor and ask even more questions about silicon carbide? You bet! We all greatly appreciated their ability to translate a brief conference into an ongoing dialog with our customers to help us understand trends in the wafer substrates that our repaired robots handle. Thank you, ladies.

The primary objective of the show this year was to introduce the Mag 7 to our service offerings. The classic, ever-popular Wafer Breaker 5000 gave many folks the excuse to hang out for a while at the booth so we could discuss their Mag 7 needs. Pleasantly we had folks from Asia, America, and Europe ask about supporting regional fabs with a large installed base of that excellent etch process tool, the Lam 2300. After a few gallons of coffee, we empirically determined that Lam must have sold buckets of these tool sets 😊. Of course, there are some good old aluminum interconnects etchers, but an extremely huge installed base of dielectric etch tools. The Kiyo innovations introduced in the 2013 timeframe, that brutal 100:1 depth: diameter etch ratio, are still being used today.

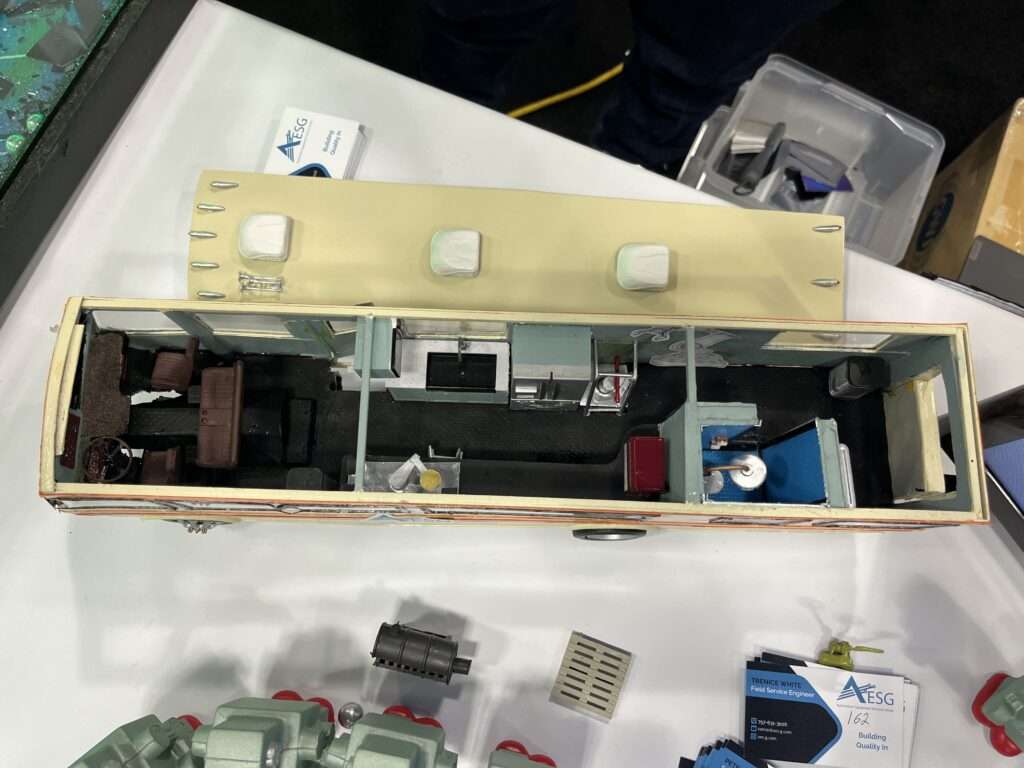

A secondary objective of the show was to gauge the market’s response to our concept of bringing Virginia Beach to the fabs. We’d retrofit an old RV with work benches, a laser vertical run-out test fixture, and a pick-and-place cycling fixture. Ah ha, the Breaking Good RV! Frank wanted it based on Breaking Bad but rebranded it because we are Breaking Good. So we made a 1/24 scale model, which was super well received. It wasn’t even past lunch on the first day when one gentleman squealed “Breaking Bad” and returned a few times until he remembered Jesse Pinkman’s name. The branding Frank wanted worked perfectly. It drew many folks in, and more than once, Frank pointed out we had no meth lab but a robot repair facility! It was a hoot.

Semicon West will be held one last time at the Moscone next year, and we’ve got our booth!

Thanks to everyone who brought us to the show and visited us!

- Category: Industrial