The Cost Factor: Repair vs Rebuild

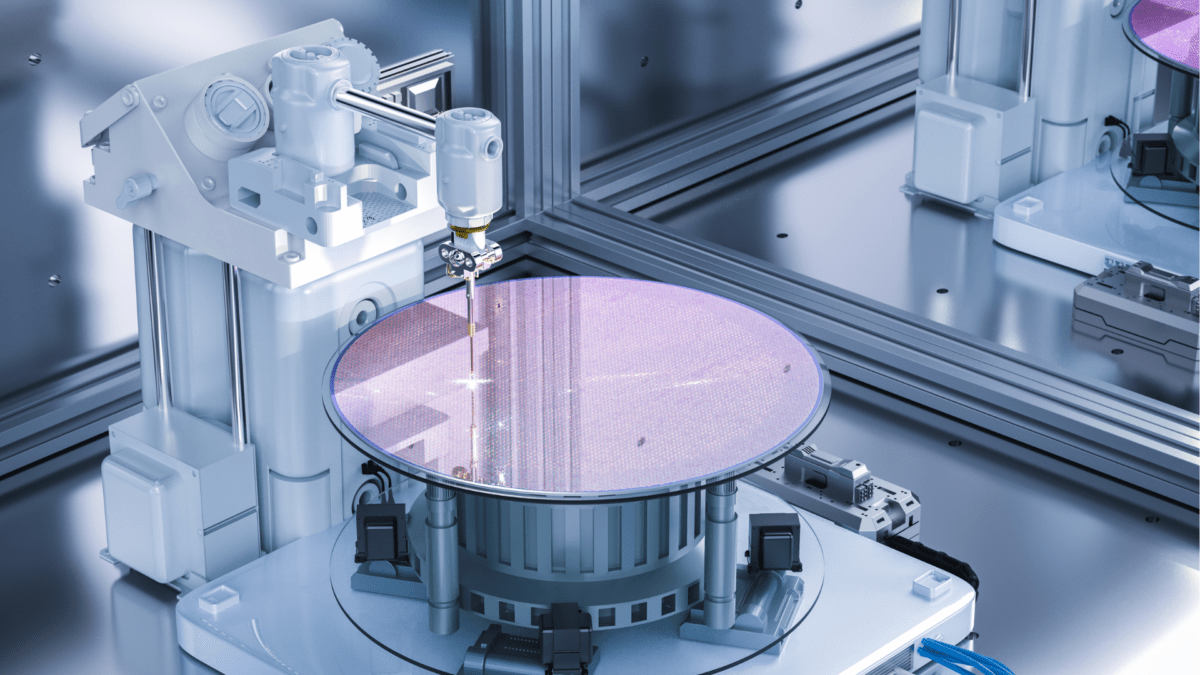

When a robot or pre-aligner fails, the immediate reaction might be to consider a replacement. However, this approach can be extremely expensive, especially when dealing with machines integrated with obsolete components. Repair or refurbishment becomes the more practical and cost-effective option in such cases. By choosing rebuild services, semiconductor manufacturers keep these qualified tools up and available and this can extend the lifespan of their existing equipment and avoid the hefty investment required for purchasing new tools, robots, and pre-aligners.

The Importance of Experience

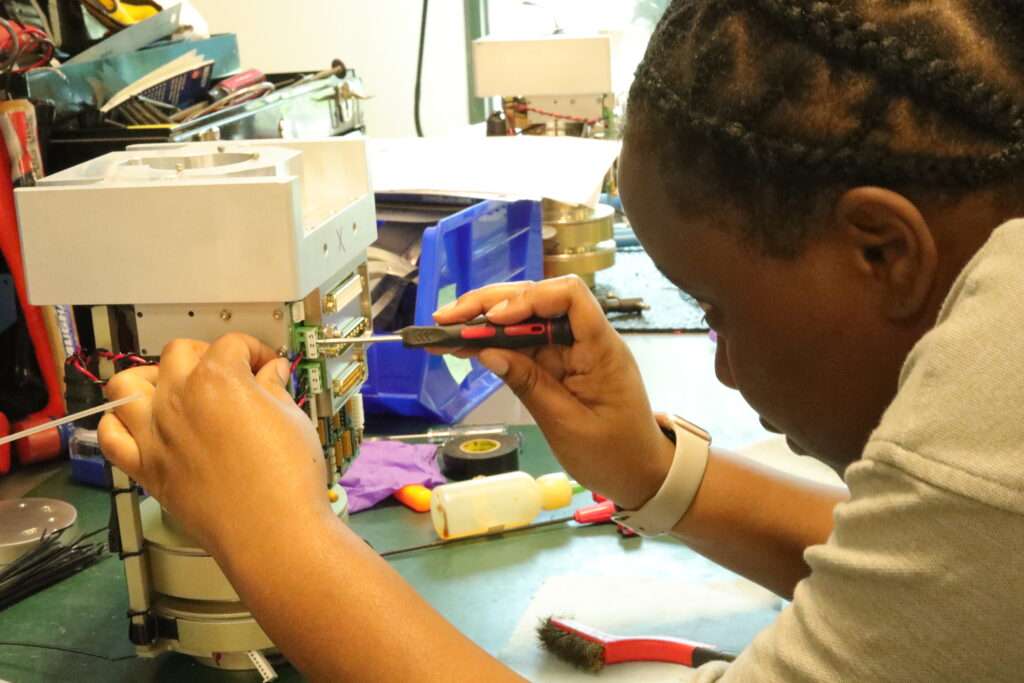

Selecting the right repair service provider is crucial for ensuring the successful restoration of robots and pre-aligners. Experience should be a critical factor in this decision, encompassing the corporate history of the service and maintenance company and the expertise of its personnel. Working with professionals with extensive experience in repairing and maintaining robots and pre-aligners specific to the semiconductor industry is essential. Moreover, these technicians should possess up-to-date qualifications and certifications to ensure that the repair work is performed precisely and by industry standards.

AESG: Your Trusted Partner in Robot and Pre-Aligner Repair

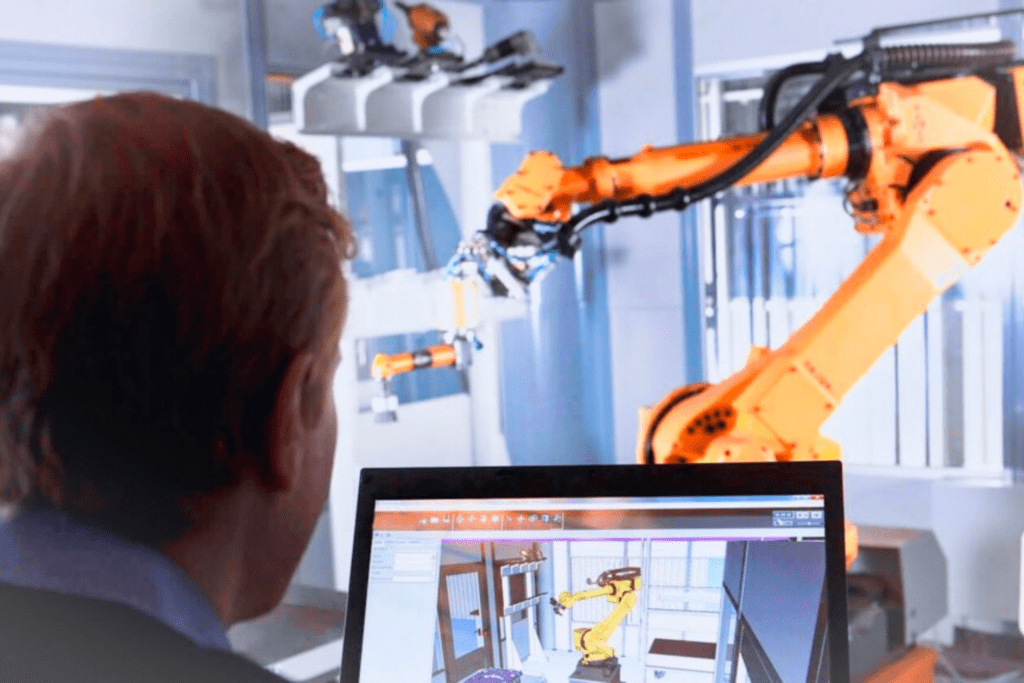

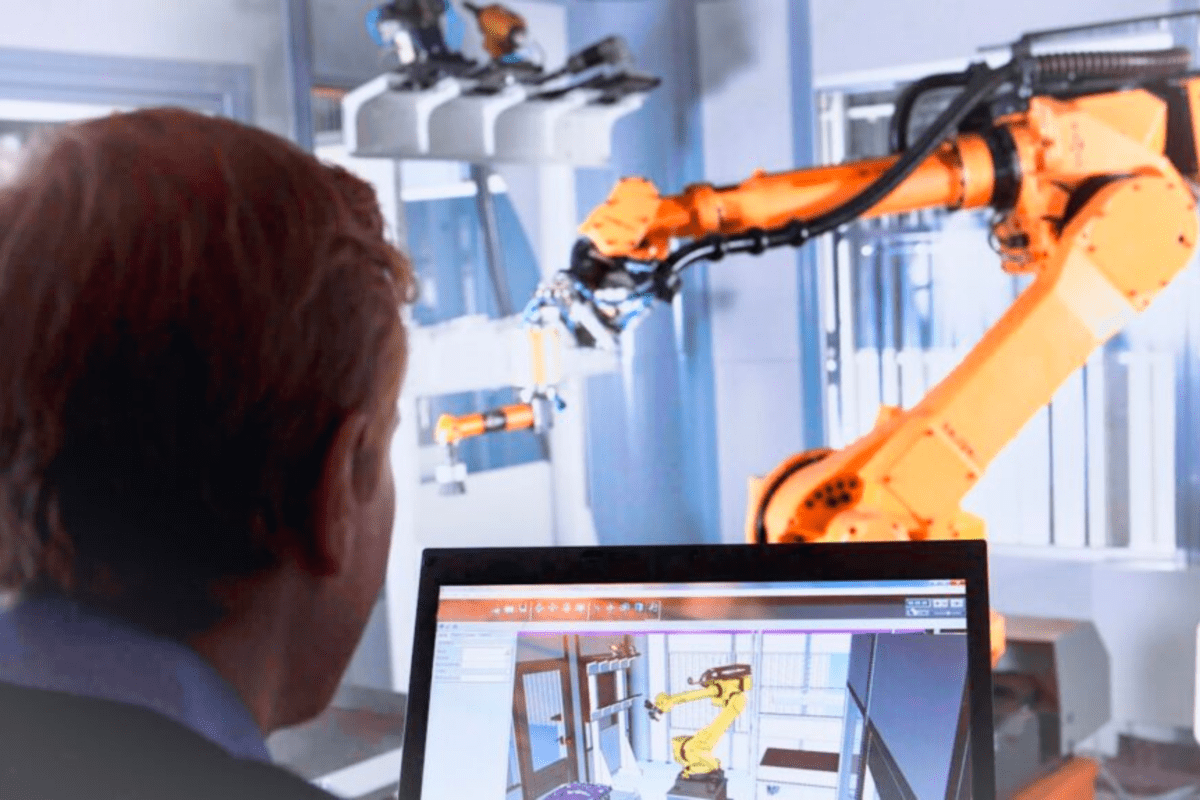

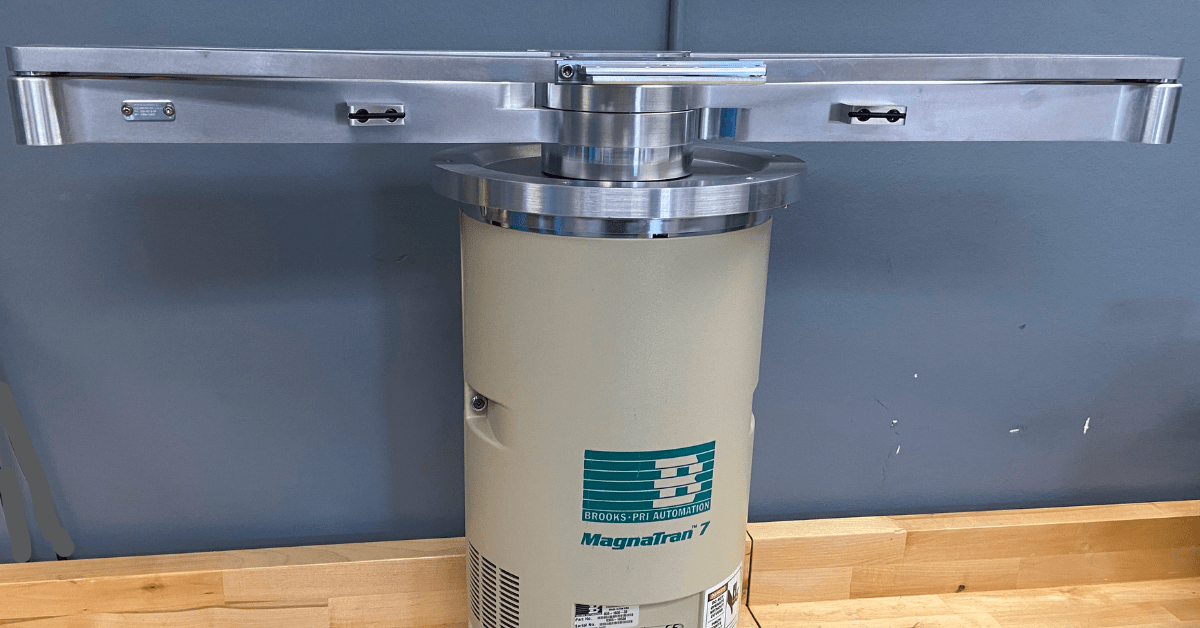

AESG is widely recognized as an industry leader in the semiconductor robotics repair sector. Starting with repairing and maintaining laser wafer marking systems, AESG expanded its services to include robots and pre-aligners as these technologies have evolved. When fixing these crucial components, AESG techs undergo comprehensive training and are qualified to deliver exceptional results. Equipped with a wide range of spare parts, we offer a range of services tailored to meet the specific needs of semiconductor manufacturers.

Functional Rebuild: Restoring Performance and Reliability

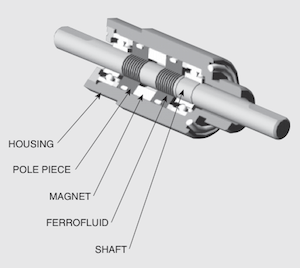

One option provided by AESG is a straightforward, functional repair focusing on addressing the specific issues affecting the robot or pre-aligner, typically referred to as FIX ON FAIL. Our techs identify and fix the root cause of the problem, replacing any failed parts and recalibrating the machine to restore its optimal functionality. This approach ensures that the repaired robot or pre-aligner performs reliably and meets the required performance standards.

Complete Refurbishment: Restoring Like-New Condition

Another option worth considering is a complete refurbishment of the robots and pre-aligners. This service goes beyond functional repair, aiming to bring the machines as close to their original condition. AESG’s full refurbishment process includes replacing worn-out components, conducting a comprehensive inspection and cleaning, and applying any necessary upgrades. The result is a rejuvenated robot or pre-aligner that functions like new at a fraction of the cost of replacing the entire equipment.

The Advantages of AESG’s Approach

By choosing AESG for robot and pre-aligner maintenance and repair needs, semiconductor manufacturers gain access to various benefits that contribute to the seamless operation of their production processes. These advantages include:

- Experience: AESG’s extensive experience in the semiconductor industry ensures that its team possesses the knowledge and skills required to handle complex repairs and maintenance tasks.

- Expertise: AESG specializes in robot and pre-aligner repairs, staying up-to-date with the latest technological advancements to provide clients with cutting-edge solutions.

- Efficiency: With a dedicated team of qualified technicians, AESG offers quick response times, minimizing downtime and ensuring production processes continue at peak efficiency.

- Total Cost of Ownership: Improving asset utilization that improves financial performance.

When faced with repairing or replacing robots and pre-aligners in the semiconductor industry, semiconductor manufacturers can benefit significantly from choosing experienced repair service providers like AESG. By opting for repair services, manufacturers can extend the lifespan of their equipment, avoid costly replacements, and ensure that their production processes continue to operate at peak efficiency. With AESG’s expertise and dedication to quality, semiconductor manufacturers can trust that their repairs will be handled by skilled professionals, delivering exceptional results and enabling them to focus on their core business operations.

For a custom-made service offering tailored to meet your specific needs, please get in touch with us.

aesg1

on

December 19, 2023